Wood Grinder Parts

1.Essential Details:

Precision Machining: Crafted precisely to meet the specifications outlined in the customer’s drawings. Additionally, we provide expert advice on optimal sizing to ensure accurate installation of all products.

2.Product Overview:

Premium Material Selection: Our products are crafted from a diverse array of top-quality materials, including alloy steel, carbon steel, and tungsten carbide.

Innovative Manufacturing Techniques: Utilizing cutting-edge methods such as laser cutting, CNC machining, and precision carbide brazing, we guarantee unmatched product quality and performance.

Get Samples

Lead time:

| Quantity (pieces) | 1 – 2 | 500-3000 | > 3000 |

| Lead time (days) | 10 | 35 | 40 |

Purchase details

Payments: T/T, Credit Card,

……

……

Why Can SKYMECH Successfully Produce H-Q Wear Parts?

Core Competition Advantages:

- Rely on our cutting-edge production facilities to deliver consistently stable and top-tier wear parts.

- Elevate performance with wear parts featuring full carbide inserts, boasting a remarkable 10-fold increase in working life compared to traditional steel alternatives.

- Leverage our extensive 17-year track record of professional expertise in manufacturing for unparalleled industry experience.

- Ensure exceptional durability with the use of high-quality alloy steel and 100% virgin tungsten carbide in our wear parts.

- Explore customization possibilities with our OEM acceptance, allowing you to tailor solutions to your unique needs

About quality

1. Tungsten carbide particles:

The broken raw material tungsten carbide with double-grain structure has high wear resistance, and we only use the highest grade tungsten carbide as the raw material of the knife tip for Wood Grinder teeth.

2. Steel body:

In SKYMECH, we use 42crmo alloy steel, one of the highest grade steel materials. It has a hardness of up to 42-55 HRC, which provides strength to the tungsten carbide tip.

3. Hard surface:

CR-W has excellent wear resistance and impact resistance. We use special CR-W or chrome to make a wear-resistant welding layer on the tool surface, and the hardness can reach 55hrc-60hrc.

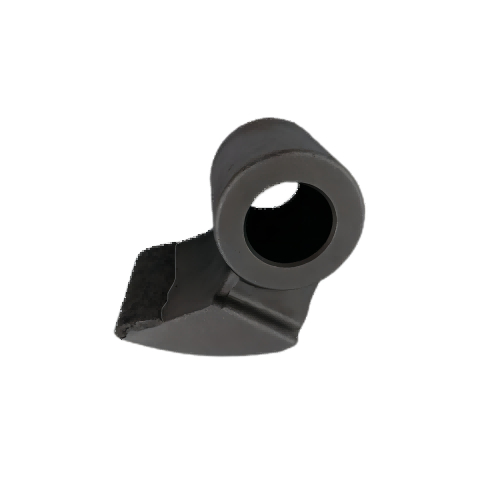

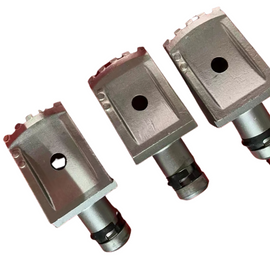

About Wooden/Stump Grinder Teeth & Pocket

Efficient forestry resource grinding:

The Wood Grinder wear-partis specifically designed to be ideal for processing a variety of forestry resources quickly and efficiently. Whether it’s logs, branches, leaves or other wood waste, these crushing teeth can easily crush it into smaller particles to meet your processing needs.

Sturdy and Durable:

Our wooden grinder teeth are made of high-quality materials with excellent wear resistance and loss resistance. This means that they can not only last long in harsh environments, but also reduce the frequency of maintenance and replacement and improve production efficiency.

Environmentally friendly and sustainable:

Wood Grinder wear-part not only helps to utilize forestry resources efficiently, but also helps reduce waste and promote sustainable resource management. By shredding and recycling wood waste, you can do your bit for the environment.

Versatile Applications:

These Wood Grinder wear-part are suitable for a variety of applications, including forestry, wood processing, waste management and the bioenergy industry. No matter what your needs are, the wooden grinder teeth can deliver superior performance.

Customized options:

We offer a variety of different models and specifications of grinding teeth to meet different equipment and processing requirements. We can also provide customized solutions based on your specific needs.

Experienced Team:

Our team has extensive experience and expertise and can provide you with professional advice on product selection, installation and maintenance.

COMPETITIVE PRICE:

Wood Grinder wear-part offer superior performance, but we’re also committed to offering competitive prices to fit your budget.

A stump grinder is a heavy piece of equipment fronted by a rotating carbide-tipped steel wheel. We put the wheels on the edge of the stump and move it side to side as it spins. Then every movement goes deep into the stump. Finally, the entire stump will be ground into small wood chips, this includes the tap root underneath the stump.

Our cutting tools and wear parts are used in grinding machines, including stub grinding and stub cutters. We also produce stumps, stubs, pockets, brackets, cutting wheels, bolts, etc. The stump grinder is a heavy duty piece of equipment with a rotating carbide tipped steel wheel in front. We put the wheels on the edge of the stump and move it side to side as it spins. Then every movement goes deep into the stump. Finally, the entire stump will be ground into small wood chips, this includes the tap root underneath the stump.

We produce and sell wear parts for all major brands and all models on the market. However, we are not affiliated with the original equipment manufacturers who manufacture and sell parts/accessories. We only use their product names, machine model numbers, components and other product details to help you determine the compatibility of our products with your machine. We are an aftermarket wear parts manufacturer completely independent from OEMs. All original equipment related trademarks, and all products advertised on this site are designed and sold for the markets in which they are used.