Carbide Teeth

SKYMECH supplies top and consistent quality welding teeth & bits for horizontal directional drilling (HDD) machines.

Our welding bits are perfect replacements for Kennametal welding teeth & bits.

Model Number:

Kennametal:RT1, RT2, DT50, DT87,BR1, BR2, BR3, BR4,U7, U7L, CJ2

Material: Tungsten carbide: YG11C, HRC88-92 + 42CrMo.

Get Samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Purchase details

Payments: T/T, Credit Card,

……

……

If you need other models,

please contact us as well.

Our Advantages Of Welding Teeth

SKYMECH’s high quality carbide teeth are available in a variety of shapes includingCoal Cutter Picks,round shank teeth 、round shank chiseland 、Trenching Bits 、Motor Grader Carbide Bits and so on.

1. Selected grade of tungsten carbide ensures greater hardness for better cutting performance.

2. Hardness and toughness of the steel body: special heat treating and hardening to achieve the optimum hardness and to maintain the necessary ductility.

3. Well executed brazing process to combine the carbide tip and the steel body firmly together.

4. Quality control: inspection during production and test after production are performed for consistent quality.

Our professional engineering team is available to review your drawings, to check your samples, and to discuss your needs for quality replacement wear parts applied on different hardness of wear fields.

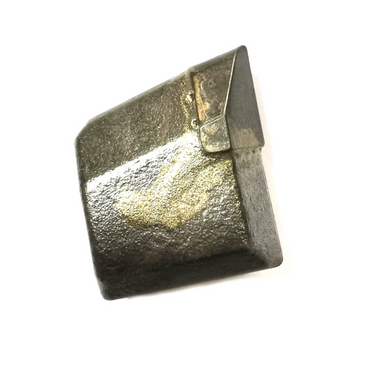

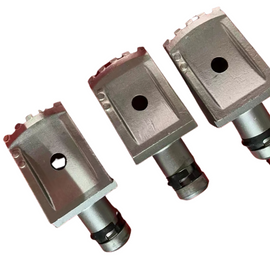

Product Display

Detals Of HDD Welding Bits

HDD welding teeth are specialized cutting tools used in horizontal directional drilling (HDD) operations. HDD welding teeth are designed to cut through different types of soil, rock, and other materials encountered during the drilling process.

HDD welding teeth are specialized cutting tools used in horizontal directional drilling (HDD) operations. HDD welding teeth are designed to cut through different types of soil, rock, and other materials encountered during the drilling process.

These welding teeth are typically made of high-quality tungsten carbide, which is a very hard and durable material that can withstand extreme wear and tear. The tungsten carbide is usually brazed onto the steel body of the welding tooth to create a strong bond that can withstand the forces exerted during drilling.

There are many different types of HDD welding teeth available, with varying shapes, sizes, and cutting patterns. Some of the popular brands of HDD welding teeth include Ditch Witch, Vermeer, American Augers, and Astec Underground.

You May Like

FAQ

We are a factory with nearly 20 years of production experience.

All products will be tested before mass production, we will check the physical performance, shape and tolerance of the product before shipment to ensure the product is qualified.

If the product quantity is small, we suggest to use express, such as DHL, UPS, TNT, FEDEX.

If the product quantity is large, by sea.

Yes, we handle OEM orders. That means the size, quantity, design, packing scheme, etc. will depend on your requirements; your logo will be customized on our products if required.

The normal models we have molds need 7-15 days after receiving the advance payment.

For non-standard we don’t have mould, it will take 15-35 days after receiving the advance payment.