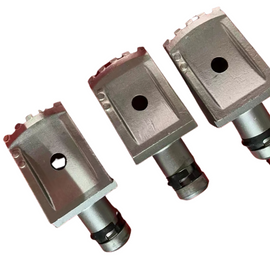

Rock Auger Teeth

SKYMECH offers a wide range of popular picks on the market

Compatible Brand:

For BETEK: B47K17.5-H、B47K19-H、B47K22-H、B47K17.5-L、B47K19-L、B47K22-L、B43H、B85/2、B87K、BHR3

For Kennametal:RL01、RL02、RZ05、RZ07、C10AMC、C21HDX、C21HDG、C21HDT、C23R、C31HD

For Sandvik:RZ05、RZ07、RZ08、RZ19、RZ20、RZ16

For AID :Shearer series: U82, U84,U85, U92, U94,U95,U170;Roadheader series: U47,U135, S150

Get samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Customized logo

Customized packaging

Graphic customization

Shipping: Contact us to negotiate shipping details

Payments: T/T,![]()

![]()

![]()

![]()

![]()

SKYMECH More Auger Teeth

Trenching Auger Bits Material Selection

Rock Bullet Teeth Video Display

High quality alloy steel

High quality alloy steel, cold extrusion and warm extrusion process,We have established long-term cooperation with famous alloy manufacturers at home and abroad. According to our company’s demand for convenient alloy shape and performance, we independently develop molds and study new processes.

Automatic brazing、quenching

At present, the domestic most advanced cutting production line, set cutting cleaning treatment, alloy welding, tooth quenching, overall tempering, overall anti-rust treatment is equal to one.

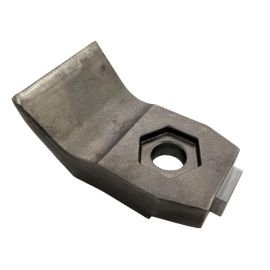

Automatic wear-resistant surfacing

A wear-resisting layer of 3-5mm thickness is surfacing on the effective cutting part of the cutting gear. The raw material is wear-resisting welding powder imported from the United States. The hardness of the surfacing layer can reach more than HRC60 (usually between HRC45-48).

Strict inspection

Professional instrument testing products surface quality, internal and external hardness, welding fullness, independent testing room and advanced monitoring equipment, including hardness tester, metallographic analyzer and two-position measuring instrument, to ensure 100% quality.

ISO9001 quality certification

products meet the international standard ISO9001 quality certification, can continue to provide customers with expectations and satisfaction of qualified products.

High standard packing

Bullet teeth、rock auger teeth、coal mining bits、trenching bits … are placed in a high standard custom bucket, packaging bucket design is easy to handle, unified standards, both beautiful and practical.