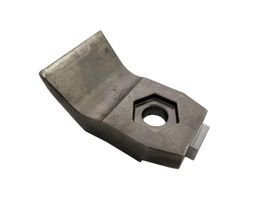

SKYMECH Drum Cutter Conical Bits

Select high-quality cemented carbide produced by international well-known enterprises.

Combined with high-quality steel matrix, various cutting tools are developed and produced to meet the needs of coal mines,

non-ferrous metal mines,

tunnels and other construction conditions at homeland abroad.

Good wear resistance, Long service life, convenient replacement and high work efficiency.

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Payments: T/T, Credit Card,

……

……

- DISCLAIMER:

All brands mentioned on this website, including Wirtgen® and Kennametal®, are registered trademarks. Any references to these brand names on this website are solely intended for the purpose of distinguishing the intended use of the products. Our company and this website do not have any sponsorship or authorization from the aforementioned brands, and we do not use or imply the use of these brands for any commercial purposes. The products showcased on our website are not endorsed or affiliated with the mentioned brands.

what is coal cutting teeth ?

Coal cutting teeth, also known as coal picks or coal cutter bits, are specifically designed tools used in mining operations to cut through coal seams. These teeth are typically attached to mining machinery, such as continuous miners or longwall shearers. The primary function of coal cutting teeth is to effectively break and extract coal from the rock strata, enabling efficient coal mining processes.

what is tunneling teeth ?

Tunneling teeth, also referred to as TBM cutters or tunneling bits, are essential components in tunnel boring machines (TBMs). These teeth are designed to excavate and remove soil, rock, or other geological materials during tunneling projects. Tunneling teeth are engineered with robust and wear-resistant materials to withstand the demanding conditions encountered during the tunneling process. Their function is to effectively break and dislodge the ground material, allowing the TBM to advance through the tunnel while creating a smooth bore.

what is rotary drilling teeth?

Rotary drilling teeth, also known as auger bits or drilling teeth, are used in rotary drilling operations for various applications, including foundation drilling, geotechnical exploration, and mineral extraction. These teeth are attached to the cutting head of the drilling equipment, such as a drill rig or an auger drill. The primary function of rotary drilling teeth is to penetrate and break up the subsurface formations, such as soil, rock, or ore, by rotating and applying downward force. This allows for the extraction of core samples, installation of foundations, or accessing underground resources. The design and composition of rotary drilling teeth vary depending on the specific drilling requirements and the properties of the formations being drilled.