Surface Mining Bit

Surface Mining Bit

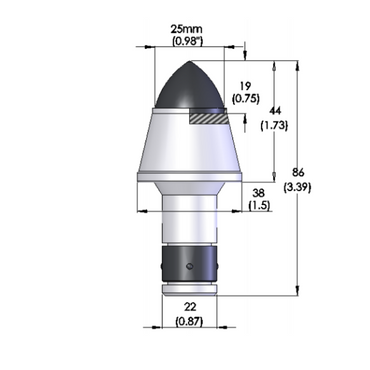

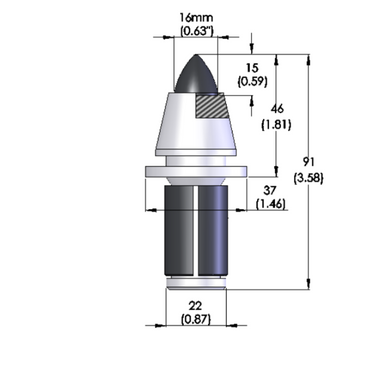

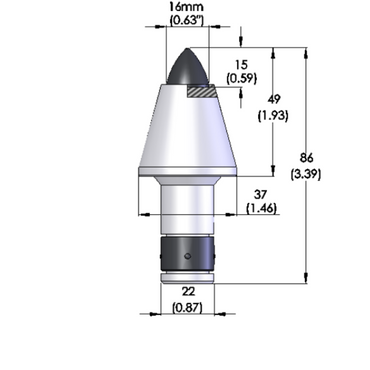

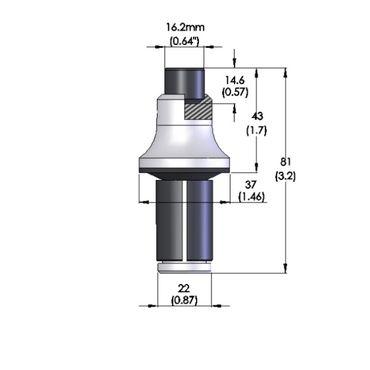

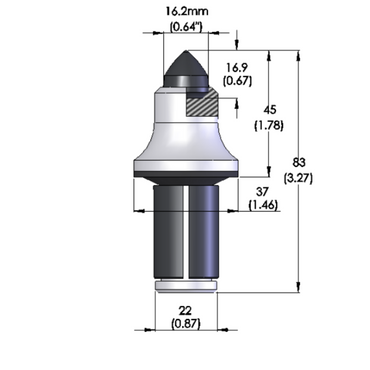

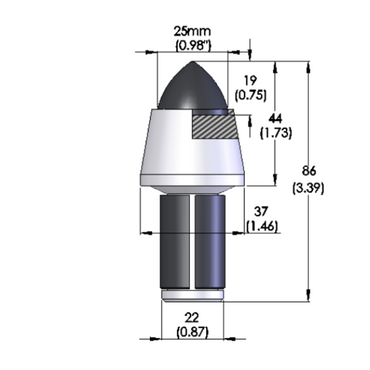

(1) Shank: 22mm (0.87″)

(2) Carbide tips: Flat-bottom

(3) Package: in plastic box

(4) Supply ability: 50000pcs/month

(5) Delivery time :20days

Get Samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Purchase details

Payments: T/T, Credit Card,

……

……

If you need other models,

please contact us as well.

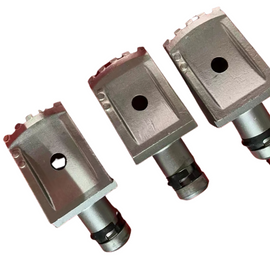

Our Advantages Of Surface Mining Bit

Our surface mining bits are made by material 40Cr or 42CrMo, heat treatment with 40-44HRC hardness, has high toughness and wearable character. Tip is made from Low press Sintered, and Suitable Grade Selected according to the Target Projects, Which are to make sure the good performance during working.

it is cheap, can recover more of the resource (usually up to 100% within the mining excavation), is safer and can use larger-scale mining equipment offering higher production rates.

Surface mining enables you to go beyond scratching the surface. With better size control and fewer hazards, it can simplify operations and save you management costs—there is no blasting considerations and no downtime related to transitioning operations. Whether you need tooling or wear protection solutions, we have high-performance products to make you even more productive and profitable.

Detals Of Surface Mining Bit

production process Of Surface Mining Bit

Type' of Surface Mining Bit

There are several models of surface mining teeth, each with its own unique design and characteristics.

- Conical bits: These are cone-shaped bits that are widely used in surface mining. They have sharp, conical teeth designed to penetrate hard rock formations.

- Wedge bits: These bits have a tapered shape, with the tip resembling an inverted wedge. They are effective for drilling through softer rock formations.

- Chisel bits: Chisel bits have a straight, flat cutting edge and are commonly used for drilling in sandstone and other sedimentary rocks.

- Button bits: These bits have rounded inserts made of tungsten carbide and are generally used for drilling in hard rock formations.

- Diamond bits: Diamond bits use industrial-grade diamonds to cut through rock and other materials. They are highly durable and can withstand extreme temperatures and pressure.

- Auger bits: Auger bits are used for drilling holes quickly in soft to medium-hard soil and clay.

The choice of surface mining teeth model will depend on various factors such as the type of rock or material being drilled, the depth of the hole being drilled, and the desired rate of penetration.