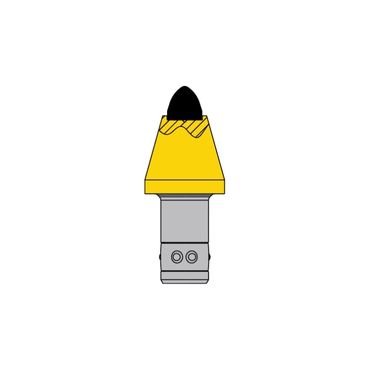

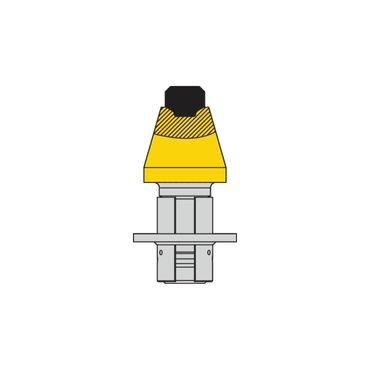

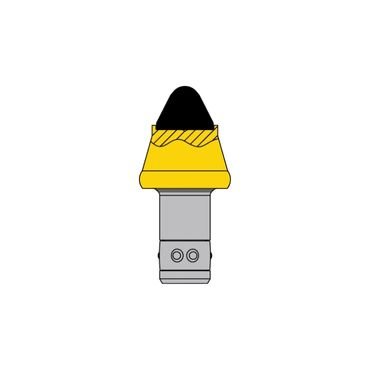

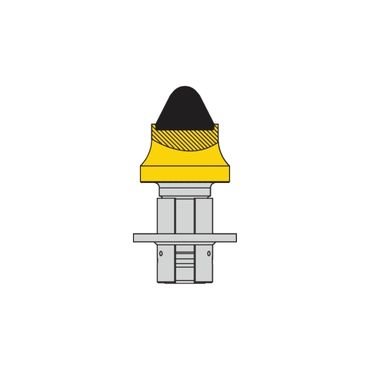

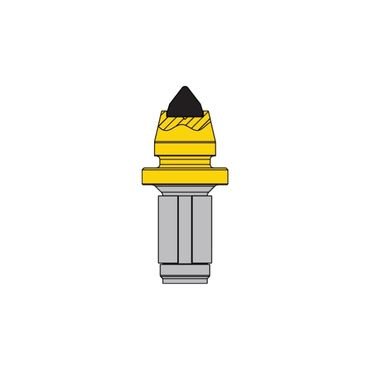

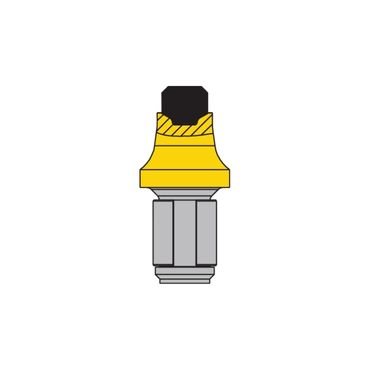

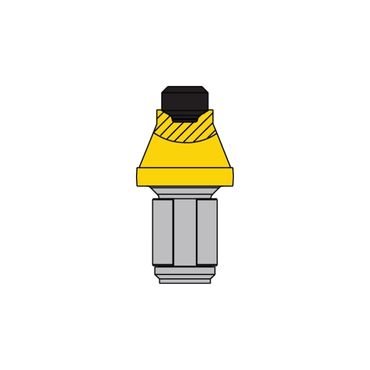

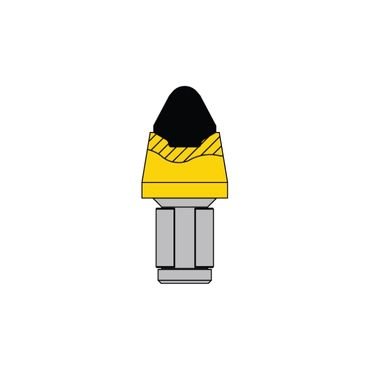

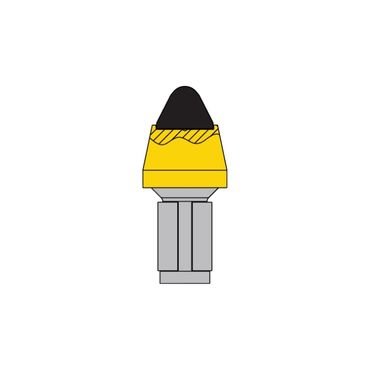

Scarifier Carbide Bits

SKYMECH supplies Scarifier Carbide Bits with high and consistent quality for the construction and mining industries.

Compatible Brand:BETEK,Kennametal

Model Number:

Sandvik :C855LR、C855HDX

KENNAMETAL: C87WFRKCSB 、C87HDRP、C87KCSBSR、C387DS、C87DSSR、C855KCSB、、C100 24.43SB、C858KCSB、C855HD、C855HDX-4、C855HDX、C855LR

CAT:1055183、1055180、6Y4339、6Y4340

Get Samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Purchase details

Payments: T/T, Credit Card,

……

……

Also we can make all kinds of Scarifier Carbide Bits according to customer sample or drawing.

Our Advantages Of Scarifier Carbide Bits

- 1、Tungsten carbide-tipped bits outlast the standard wear life when compared to conventional grader blades.

- 2、Scarifier blade systems are designed with the ability to individually replace bits and small scarifier sections so that they can be easily repositioned along a moldboard to maintain a consistent cutting height and straight edge. Plus, the bits are rotating and self-sharpening so that each bit will wear more uniformly and last longer than flat blades.

- 3、Individually replaceable scarifier bits allow a single person to change the cutting edge in a matter of minutes, without any special tools, which reduced downtime and operator maintenance time.

- 4、Reduces costs associated with replacement part inventory, downtime, labor, and overall operations.

- 5、Eliminates “washboarding” and potholes with fewer passes than standard blades. Decreases the number of passes necessary to properly maintain a road surface.

- 6、Scarifier systems easily penetrate hard-packed gravel and frozen ground with less down pressure and horsepower, which saves fuel and money while operating motor graders.

- 7、Carbide-tipped systems can more effectively cut hard materials, shatter rocks, and grind off embedded rocks. This allows the road to be cut deeper and restored with fewer passes.

- 8、The grooves left by the individualized bits help to improve traction by eliminating shear planes, washboarding, and deep potholes.

- 9、Carbide steel cutting bits with free rotation absorbs some of the vibration and force of the grading operations, making it a more comfortable experience for operators and putting less wear on the overall machining equipment.

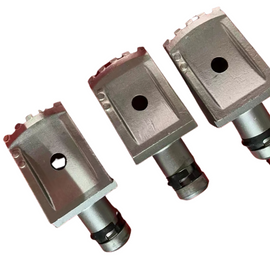

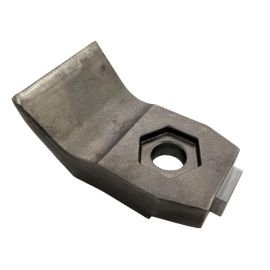

Details Of Scarifier Carbide Bits

Details of Scarifier Carbide Bits

Scarifier carbide bits are cutting tools used in scarifying machines for surface preparation and removal of coatings, adhesives, and other materials from concrete, asphalt, and other surfaces. The bits are typically made from tungsten carbide, a hard and durable material that is capable of withstanding high-impact applications. Scarifier carbide bits feature sharp teeth that grind and scrape the surface, effectively removing unwanted materials and creating a rough texture suitable for further processing. These bits come in a variety of shapes and sizes to accommodate different scarifying applications, including flail cutters, star-shaped cutters, and drum-style cutters.