Bullet Teeth

SKYMECH supplies carbide-tipped bullet teeth with high and consistent quality for the construction and mining industries.

Compatible Brand:BETEK,Kennametal

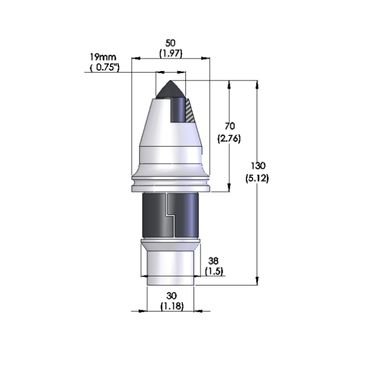

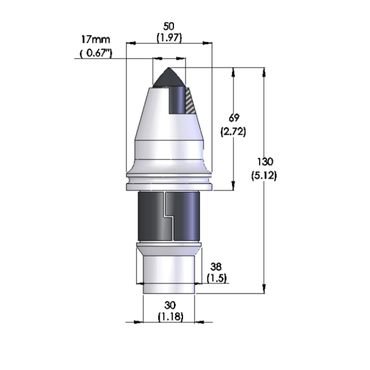

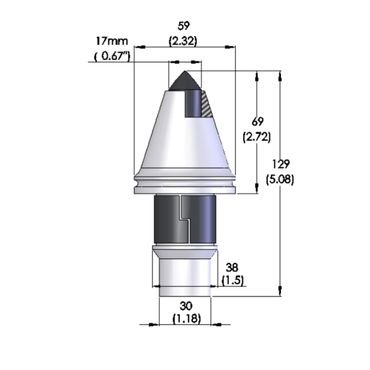

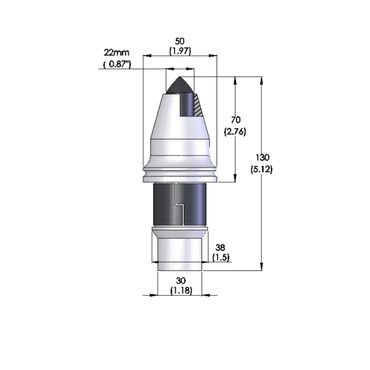

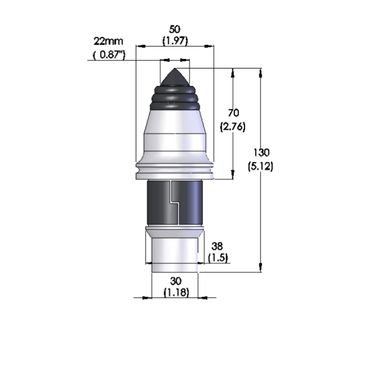

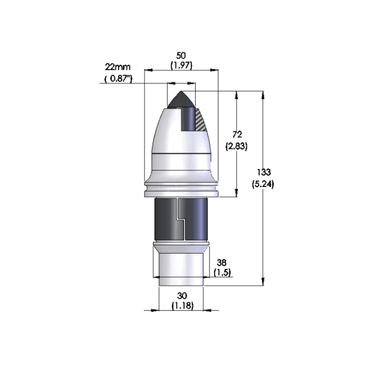

Model Number:

BETEK: BTK70, B47K19H, B47K22H, BETEK B47K25H

Kennametal: C34FSR, C23, C31HD, U40HD, DS04

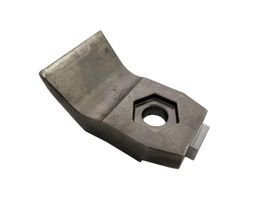

Tool Holder:B43H , B85/2, C30

Attachment Types: Auger, core barrel, bucket

Material: Tungsten carbide: YG11C, HRC88-92 + 42CrMo.

Get Samples

Lead time:

| Quantity (pieces) | 1 – 50 | 50-3000 | > 3000 |

| Lead time (days) | 15 | 20 | 30 |

Purchase details

Payments: T/T, Credit Card,

……

……

SKYMECH's Advantage of Bullet Teeth

Core competitive advantage:

- Advanced Production Equipment: Our state-of-the-art production equipment ensures the production of wearing parts with consistent and stable quality.

- Exceptional Durability: Our wear-resistant parts are crafted using all-hard alloy blades, resulting in a service life that is 10 times longer than steel counterparts.

- Extensive Manufacturing Experience: With nearly 20 years of professional manufacturing experience, we possess the expertise and knowledge to deliver high-quality products.

- Premium Materials: We utilize high-quality alloy steel and 100% pure tungsten carbide, ensuring the superior performance and longevity of our products.

- OEM Manufacturing: We offer OEM manufacturing services, accepting orders based on drawings or samples to meet specific customer requirements.

By leveraging these core advantages, we are committed to providing our customers with top-notch products that excel in quality and durability.

Details of Bullet Teeth

Four column structure hydraulic press,fuselage stability, anti – biased load ability,high stamping precision

Liquid filler metal is used to fill the gaps of solid workpiece to make the metal connection

- DISCLAIMER:

All brands mentioned on this website, including Wirtgen® and Kennametal®, are registered trademarks. Any references to these brand names on this website are solely intended for the purpose of distinguishing the intended use of the products. Our company and this website do not have any sponsorship or authorization from the aforementioned brands, and we do not use or imply the use of these brands for any commercial purposes. The products showcased on our website are not endorsed or affiliated with the mentioned brands.

Details Of Bullet Teeth

Bullet Teeth, including popular variations like B47K22H, C31, and Kennametal, are cutting tools commonly used in conjunction with Bullet Teeth Holders, Rock Augers, and Augers. These teeth, made of durable tungsten carbide, are specifically designed for drilling and excavation tasks, providing efficient and precise cutting performance. Their sharp, bullet-shaped tips enable them to penetrate tough materials such as rock, concrete, or asphalt with ease. Bullet Teeth, along with compatible pockets, ensure a secure and reliable connection to the drilling equipment. With their exceptional strength and wear resistance, these carbide Bullet Teeth are trusted by professionals in the construction and mining industries for their ability to withstand demanding conditions while maintaining cutting effectiveness.

Related Products

FAQ

The product quality is high, the price is competitive, and the after-sales service is guaranteed.

If there is a quality problem with our product, it will be reissued for free.

Ningbo, Zhejiang, China. Make an appointment with us in advance, you are welcome to visit our factory at any time.

Within 15-35 days after we confirm your request.

T/T, L/C, cash, Western Union are all ok, if you have other payment methods, please contact me.